Optimum air separation

Problem: Air inclusions as well as foam formation with oils

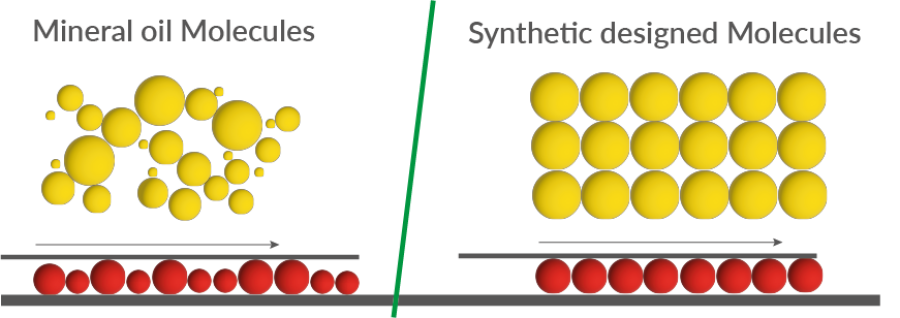

Too much air bubbles in the oil and foam on the oil surface we recognize more and more often in practice, which causes serious malfunctions. Among other things, undefined molecular chains (mineral oil, disordered molecules) of different lengths (viscosity) suppress air release efficiency. In addition different operating temperature and contamination, abrasion, water, etc., oil oxidation (aging) in grinding, hydraulic, turbine, gear and bio-oils, etc., also has a negative effect on the process performance:

-

Rinsing and clean away behavior

-

poorer delivery performance of the pumps

-

unnecessarily increased heating of the oil and pumps

-

Cavitation, material wear

-

Impairment of lubrication and cooling performance (machining oils)

-

Increase in oil compressibility

-

Seal wear is increased

-

Oil carbon deposits

Solution: Faster air separation capacity, exhaust gases.

Defined molecule chains synthetically designed (ordered and aligned) allow faster release of the air and can be filtered better. In addition to better oxidation resistance, there are fewer constantly changing physical parameter in performance, which is important in the continuous, constant operating process.

Our recommendation:

-

Grinding oil:

-

Gear oils:

-

Biodegradable hydraulic oil:

-

Industrial multipurpose hydraulic oil: (NSF H1 approved)

-

Turbine oils: (Siemens approved)

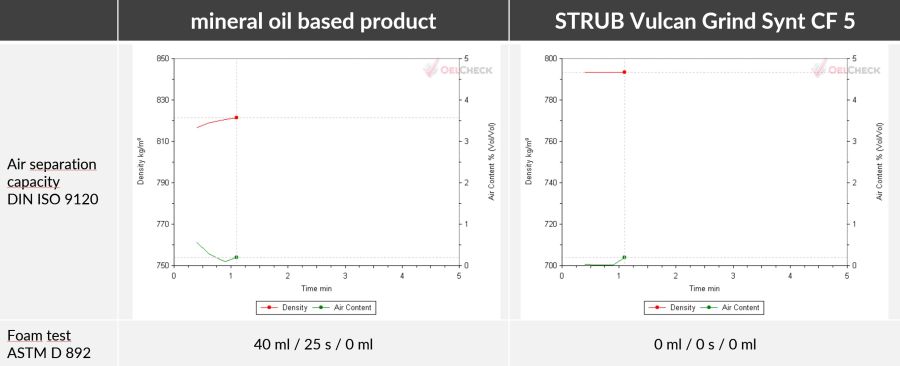

Foam test: Competitor product (mineral oil) VS. STRUB Vulcan Grind Synt CF 5 (synthetic designed) Please do not hesitate to contact our chemistry and technology department for further products or technical questions.